A/C Compressor Clutch Reshimming

#21

#22

What I have done lately is drop the right from of the subframe down a hair and loose the screw for the dryer to get it loose to swing it out of the way some. I do not remove the freon and can get it done. I myself have to do my Yellow car soon. If I do it that way I will take pics. But might end up doing it while the subframe is out for the tranny swap.

#23

I am in the middle of this on a 99 S70 non-turbo owned by a friend of mine. The air blows ice cold when the clutch is working. But, the clutch cut in and out randomly. So I checked the clearances and there was over .035 in. of room.

I did manage to do this service with the compressor still in the car. It is possible if you make a tool to hold the clutch stationary to get the 10mm bolt out with an off set box end wrench. Then undo all of the compressor bolts except for the lower left bolt. The lower left one just loosen about 5-10 turns. Once the clutch is separated from the shaft (most PITA part with screwdrivers that took me over an hour) you can rotate the compressor slightly lifting the clutch side. You will have exactly enough clearance to get the clutch out.

My mistake was not taking all of the shims out. I go at it again in the morning. I think I will take some pics along the way.

My friend is selling this car within 6 months and doubts he will get even 1500 bucks at the dealership as a trade in.

Do you think I should buy it for 1 grand if I get the chance?

I like the styling, the interior (very nice driver seat), and the overall parts content (everything under the hood is made in Sweden, Japan, or Germany). The miles are about 120K.

Why had depreciation been so bad in these cars? They were not cheap cars when new by far.

Anyway...wish me luck...even with 1 shim out I am out of spec...this thing is worn well. So another 1 or 2 will come out.

I did manage to do this service with the compressor still in the car. It is possible if you make a tool to hold the clutch stationary to get the 10mm bolt out with an off set box end wrench. Then undo all of the compressor bolts except for the lower left bolt. The lower left one just loosen about 5-10 turns. Once the clutch is separated from the shaft (most PITA part with screwdrivers that took me over an hour) you can rotate the compressor slightly lifting the clutch side. You will have exactly enough clearance to get the clutch out.

My mistake was not taking all of the shims out. I go at it again in the morning. I think I will take some pics along the way.

My friend is selling this car within 6 months and doubts he will get even 1500 bucks at the dealership as a trade in.

Do you think I should buy it for 1 grand if I get the chance?

I like the styling, the interior (very nice driver seat), and the overall parts content (everything under the hood is made in Sweden, Japan, or Germany). The miles are about 120K.

Why had depreciation been so bad in these cars? They were not cheap cars when new by far.

Anyway...wish me luck...even with 1 shim out I am out of spec...this thing is worn well. So another 1 or 2 will come out.

#24

#25

this forum is awesome!!!. I've been having the intermittent A/C issues described in many of the posts....AC blows for a 10 to 30 min in hot weather and all of suddeen does not blow cold. Must turn off AC and let it cool down for a long period and when I turn it on again most of the time it works.

It seems like alot of effort to remove the clutch plate and reshim if you don't have the right tools so I'm attempting to jerry-rig a fix. The idea is to reduce the air gap between the clutch plates and the pully by placing shims on the OUTSIDE of the clutch plates. On my 01 S80 volvo the clutch plate are kept under tension with metal flexible brackets ( see other peoples posted pictures of clutch/compressor) I can reduce the gap by placing shims between the metal brackets and the clutch plates ( Not to be confused with washer type shims previously discussed)with therefore reducing the air gap between the clutch plate and the pulley. I crudely remeasued the gap and it much less.

Hope this works...I will be using the car today and it it over 90 degrees today in San Diego

It seems like alot of effort to remove the clutch plate and reshim if you don't have the right tools so I'm attempting to jerry-rig a fix. The idea is to reduce the air gap between the clutch plates and the pully by placing shims on the OUTSIDE of the clutch plates. On my 01 S80 volvo the clutch plate are kept under tension with metal flexible brackets ( see other peoples posted pictures of clutch/compressor) I can reduce the gap by placing shims between the metal brackets and the clutch plates ( Not to be confused with washer type shims previously discussed)with therefore reducing the air gap between the clutch plate and the pulley. I crudely remeasued the gap and it much less.

Hope this works...I will be using the car today and it it over 90 degrees today in San Diego

Last edited by jzm.oside; 09-03-2009 at 01:52 PM.

#29

Your going to have to slip off the belt, undo the passenger side of the airdam (I did this up on ramps without pulling the wheel, the compressor is closer to the radiator than the wheel well anyway, so its best to get access from under the bumper area) take out the four mounting bolts for the compressor, slide the compressor back an inch or so and tweak the clutch towards the little opening your working through. At that point, you can put the 3 m5 bolts (try to get them around 25-30mm long, if they are much more you won't be able to get them started, its very tight) through the clutch, and CAREFULLY use one of them for leverage a bit to undo the center bolt for the clutch, you can also put a framing nail through one of the non threaded holes so you dont risk damaging the thread. Once the center bolt is out, start very evenly screwing in the three m5 bolts, and they should relatively easily slide the clutch off. Then pull the shims as mentioned. VERY IMPORTANT, use a bit of grease oil spit or something to ensure the shim is held in place, it can very easily fall sideways and get snagged on the splines, and you will crush it as you tighten the center bolt

one last bit of advice, grab the 1/4 drive girl wrenches after you've broke the bolts loose, and only go back to the 3/8 when your torquing them back down when your done. As a side note, I only had 2 shims in my clutch, and both were the .020 variety, I pulled one and that put me back in spec.

THANKS for posting this, saved me a boat load of cash, and got the wife/kids car back to being comfortable for them in about two hours, all for the price of .80$ worth of bolts.

maybe now I can convince her to keep it and go for a manual swap.

Last edited by metalman; 05-03-2010 at 11:25 PM.

#31

This is the right fix...There is a jury-rig fix on another forum that advises gluing plastic bread wrapper tabs under the clutch pressure fingers...It has a lot of enthusiatic adherants because it avoids removing the compressor...It is a VERY dangerous fix, since the shims could get thrown out by centrifugal force and put someone's eye out...

Once compressor is off set it like the following pic and remove the 10mm screw in the middle of the pulley.

Then carefully remove the outer part of the Clutch.(There is a special tool which I didn't have I used to screw drivers but be careful)

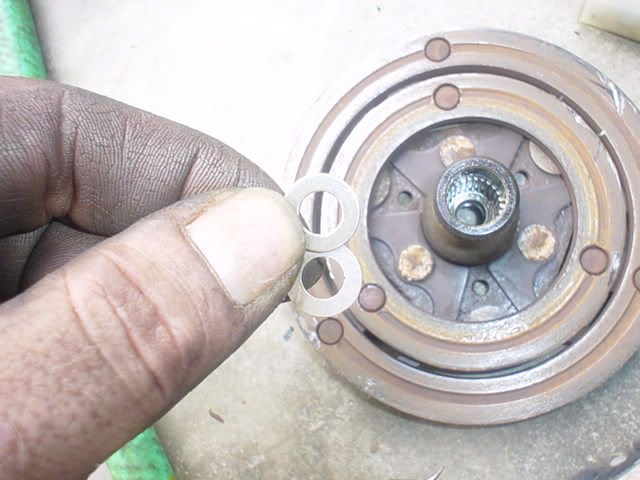

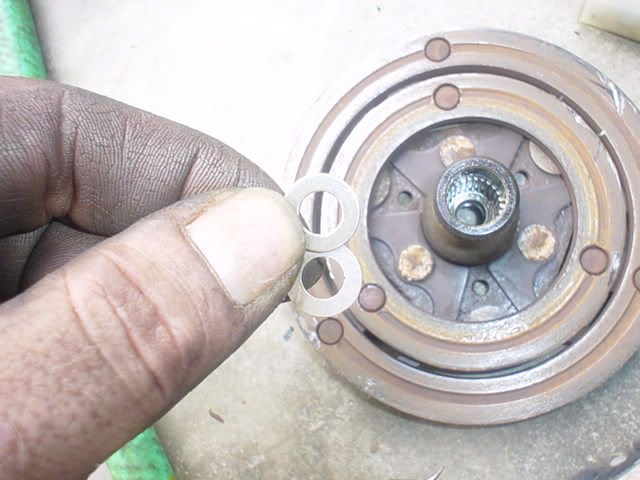

Then either the shims will come out with the outer peice like mine did or they will be sitting on the shaft once the outer part is removed.

If you look closely the washers/shims are different thicknesses. You will need to Measure the thickness and then find one a little thinner and reinstall and check the Gap between the outer and inner part of the clutch.

I will have to find out the exact specs but I believe it needs to be .016 Cannot be more than .020.

Use a fueller gauge to measure the gap.

Hopefully this helps.

If you have any qioestions feel free to ask.

Compressor Specs: Gap should be between .3MM(.012Inches) and .5MM(.020Inches)

.6mm(.024) should not fit in at all

Then carefully remove the outer part of the Clutch.(There is a special tool which I didn't have I used to screw drivers but be careful)

Then either the shims will come out with the outer peice like mine did or they will be sitting on the shaft once the outer part is removed.

If you look closely the washers/shims are different thicknesses. You will need to Measure the thickness and then find one a little thinner and reinstall and check the Gap between the outer and inner part of the clutch.

I will have to find out the exact specs but I believe it needs to be .016 Cannot be more than .020.

Use a fueller gauge to measure the gap.

Hopefully this helps.

If you have any qioestions feel free to ask.

Compressor Specs: Gap should be between .3MM(.012Inches) and .5MM(.020Inches)

.6mm(.024) should not fit in at all

#32

something I highly recommend, you can replace it on the car (without purging the AC system) if you work around the wheel well and radiator on the v70 from underneath, IF and its a big IF you can get the clutch off. The trick I found is the three empty holes on the clutch are threaded, I can't remember off hand its been a few months, but its a small metric size. You'll only have enough space to put one in at a time, then rotate the clutch to put the next one in, and get a few different lengths because if they are too long they hit the frame when you try to rotate the clutch, its silly tight working around it. but yeah this thread saved me a few hundred bucks and a very pissed wife (she doesn't do hot weather).

#33

Before you go to all this trouble, check voltage going to clutch. The only three 850's that I have seen with this problem 2 mine and third a friend. I solved with a relay wired into the clutch power wire. Seems that I found there was only 8.5-9.7 volts constant to clutch. $7.00 and ten minutes and never had another problem.

#34

Hello there. I saw your posting on this issue and became curious. Now I am NOT savvy with cars and stuff, although I am a handyman and have fixed various things in various cars before, but I don't know terms and part names like I would have to in order to be a "car repairman". All I do when I need to fix something is I use google + youtube and voila... I can get things done. I am a hands-on type of person.

I have a 2001 V70 and my a/c works at times and at times it just decides not to work. When it works it is always ice cold. When it doesn't, if I speed off real quick or hit a pot hole, it sometimes kicks it back on. Once in a very blue moon (I mean, verrryyyyyy blue moon) the whole panel turns off and stays off for a little while and when I turn the car off and leave it off for the night, the next morning the panel lights up just fine. I don't think I have a leak, nor it needs freon. The a/c is COLD! But for whatever reason, it decides to turn off and on whenever. It has a mind of its own. Now, please note it doesn't go off and on all the time while I'm driving. If I start the car and it is working, it works for quite a while, sometimes days. But if I start the car and it doesn't start, that's when the speeding off and pot hitting begins. I don't want to keep doing this because I am not an offensive driver nor I want to bend my wheels or anything worst, but when it's 110F outside, one desperately uses all tools to start the dang thing. Please help if you can and shed some light.

I have a 2001 V70 and my a/c works at times and at times it just decides not to work. When it works it is always ice cold. When it doesn't, if I speed off real quick or hit a pot hole, it sometimes kicks it back on. Once in a very blue moon (I mean, verrryyyyyy blue moon) the whole panel turns off and stays off for a little while and when I turn the car off and leave it off for the night, the next morning the panel lights up just fine. I don't think I have a leak, nor it needs freon. The a/c is COLD! But for whatever reason, it decides to turn off and on whenever. It has a mind of its own. Now, please note it doesn't go off and on all the time while I'm driving. If I start the car and it is working, it works for quite a while, sometimes days. But if I start the car and it doesn't start, that's when the speeding off and pot hitting begins. I don't want to keep doing this because I am not an offensive driver nor I want to bend my wheels or anything worst, but when it's 110F outside, one desperately uses all tools to start the dang thing. Please help if you can and shed some light.

#35

#36

something I highly recommend, you can replace it on the car (without purging the AC system) if you work around the wheel well and radiator on the v70 from underneath, IF and its a big IF you can get the clutch off. The trick I found is the three empty holes on the clutch are threaded, I can't remember off hand its been a few months, but its a small metric size. You'll only have enough space to put one in at a time, then rotate the clutch to put the next one in, and get a few different lengths because if they are too long they hit the frame when you try to rotate the clutch, its silly tight working around it. but yeah this thread saved me a few hundred bucks and a very pissed wife (she doesn't do hot weather).

On the V70, there is no need to remove the compressor from the vehicle. To provide room to work, the lower black plastic air deflector/spoiler (or whatever this item is called) needs to be removed from behind the front bumper and I also removed the right front tire to gain access to the compressor via removal of the fender well fasteners and bending the plastic fender well out of the way.

Next, the four mounting bolts that hold the compressor to the engine block need to be removed. I was able to use a simple 3/8 inch drive ratchet and a little creativity to work around the compressor coolant lines. After the four bolts are out, the compressor can be moved forward with the rear end tipped up, allowing clutch access from between the radiator and the engine under-carriage. The center bolt needs to be removed at this point from the clutch assembly.

There are three threaded holes where one can try to use a harmonic balancer puller. Space is limited and it's a big pain in the rear to try to support the compressor while trying to run the puller without an extra pair of hands. The easier method was to insert three M5 bolts that are approximately 1.5 inches long into the threaded holes. I found these as a normal stocked item at my local Lowes. When they bottom out, begin gradually turning all three as evenly as possible (I did 180 degree tightening rotations at a time) until the clutch hub was loose enough to remove by hand. This provided even pressure to get the clutch hub off of the splined compressor shaft.

As described repeatedly, there were two shims present on my compressor. I removed the thicker one and re-installed the hub with the thin shim in place. As a precaution and for ease of use on later issues, I applied a thin film of anti-seize on the splined shaft before re-assembly. The measured gap on re-install was .014. Everything was re-installed and I went out for a test drive in 105 degree weather on both stop and go city traffic as well as some highway 75mph maintained speed. This was the first time since I purchased this used vehicle where I've had to turn down the a/c from high fan speed because I was too cold.

Awesome forum, awesome instruction to get me started, and awesome results!

Thank you tech for the inspiration and thank you metalman for the additional hints.

#38

worldbound4now

You could have just pulled the cooling fan from infront of the radiator and then turned the compressor straight up and had more room to work.

But congrats on the good job!!!

You could have just pulled the cooling fan from infront of the radiator and then turned the compressor straight up and had more room to work.

But congrats on the good job!!!

#39

I have a 2001 S80 with the same issue, cold for 20 mins or so then hot. The clutch gap is a shade over 0.8mm so I assume I need to take out or replace a shim or two. The question is, can this be done on the S80 without taking the compressor off the vehicle, or at least without disconnecting to avoid regassing.

Thanks in advance

Thanks in advance

#40

Honestly, I haven't worked on an S80, so I couldn't say for sure. However, I have never worked on a car that required you to crack the AC system to replace the pulley or clutch, although some times thats the easiest way, its never mandatory. For example. on my v70t5, I had to pull a radiator hose, part of the front air dam, of course take off the belt, remove all the mounting bolts for the compressor, then carefully rotate the compressor so that the face of it was tilted up, then pull the front right tire so that I could get to the compressor face through the wheel well opening. loosen the bolt for the clutch, and at that point, you can use some metric bolts, really small, I think like an m4 or 6, you'll see three threaded holes in the clutch, use the bolts to press the clutch off. be careful, the threads aren't deep and if you strip them with the wrong bolt size, I don't know how you would get the clutch off, anyway, when the clutch pops off the washers will fall out. measure the washer/shims, they are different thicknesses, and pull the right ones to put the clutch back into the tight side of spec. its a free fix, other than possibly buying the weirdo metric bolts and replacing coolant, but be warned my first time getting to the AC compressor was several hours, although after having done it a couple times, I could probably do it in 20 minutes now. Most of the volvo clutches seem to have enough meat for 3 reshims, which by my math works out to about 600,000 miles. It will also last longer if you keep the fan in the vehicle on high but set the actual temprature warmer so the compressor doesn't cycle as frequently. My wife liked a just barely moving whiff of arctic air, so the compressor was constantly going on and off, I told her if she smoked the clutch again she could just roll the windows down. she goes easy on the AC now.