2000 S40 1.9L Turbo - Broken Timing Belt

#1

Greetings folks!

Yesterday I bought a 2000 S40 1.9L Turbo (B4204T) for $500. The interior is good, the body is excellent... but the previous owner opted not to replace the timing belt and at ~130k it failed. Prior to purchasing I called a junkyard and they'll give me $500 for it even if I can't do anything else, so I'm not taking a big dive either way.

Today I removed the timing belt covers, crank pulley, and engine mount and installed a new belt (as close to aligned as I can without the crank/cam holding tool... I have purchased one and it's on the way)

Good news is cylinders 1,2, and 4 have good compression (~170 +/- 10 psi) but cylinder 3 is flat dead. I knew it I'd likely have some bent valves, and I've done a few backyard head pulls and head jobs before, but this will be my first Volvo. I guess I'm lucky it's only the one cylinder.

I have a couple of questions now. I have a copy of the VIDA software (and also VADIS) but I'm having trouble getting it to run on Windows 8. Do I just need to load up XP on an old computer and do it that way or is there some trick? VIDA opens but starts throwing errors after I type in the VIN and I can't actually look at any service info.

Second question: I'm going to begin the process of pulling the head today. Has anyone done this before? Anything major to watch out for?

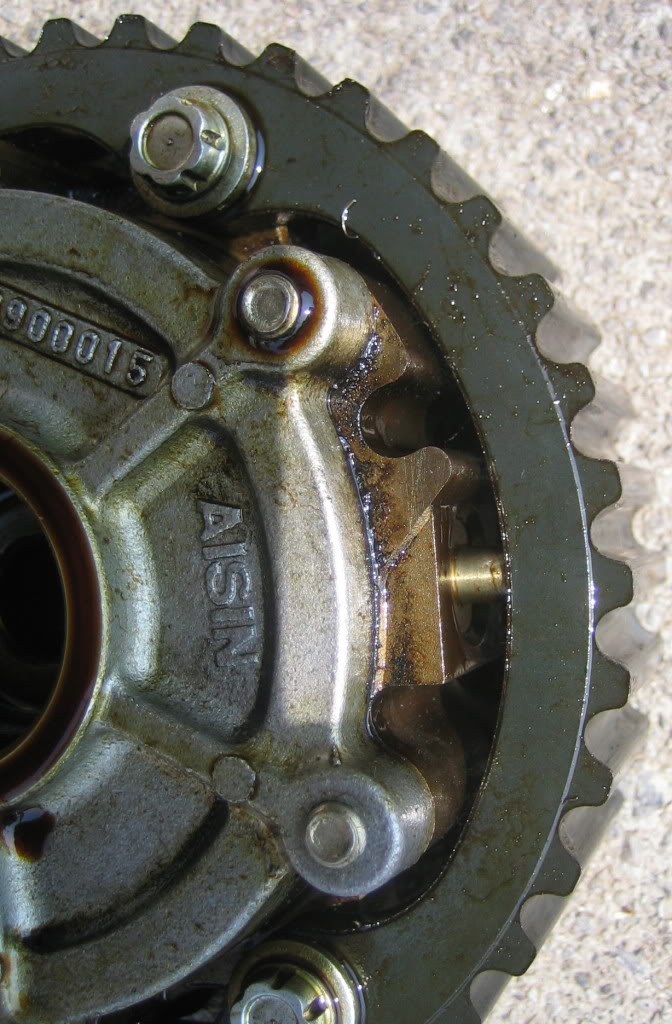

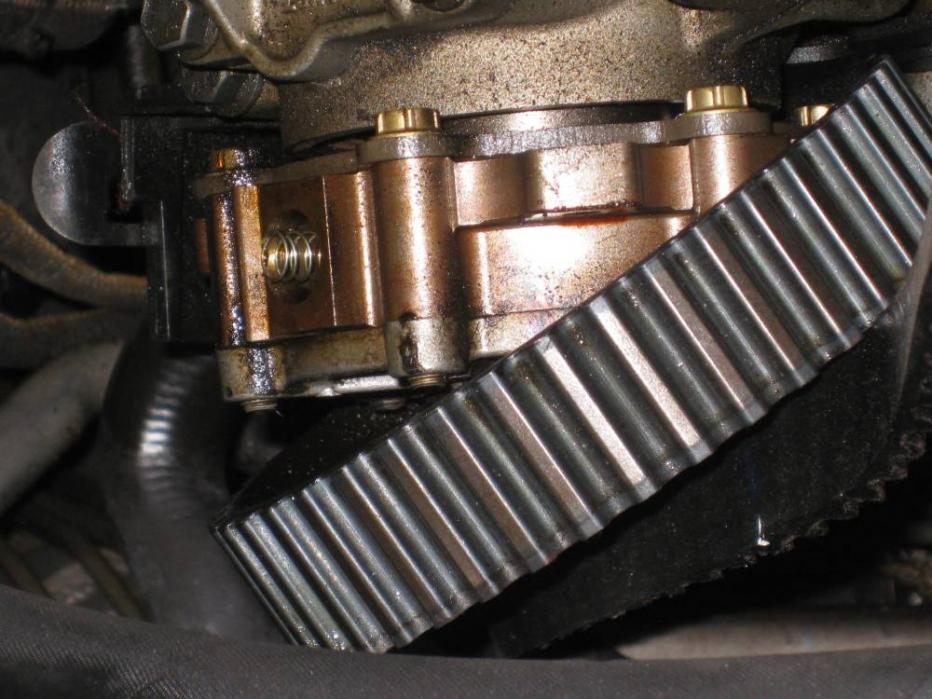

Third and final (for now) question: it looks like the belt failure was likely caused by oil getting thrown out of the VVT gear and onto the belt. I'm comfortable doing a cam seal (since I'm removing them and the engine has over 100k I'll be replacing them) but I've never done a VVT seal. Any tips?

Thanks a ton guys, and I look forward to joining you on the road in a couple of weeks!

Jon

Yesterday I bought a 2000 S40 1.9L Turbo (B4204T) for $500. The interior is good, the body is excellent... but the previous owner opted not to replace the timing belt and at ~130k it failed. Prior to purchasing I called a junkyard and they'll give me $500 for it even if I can't do anything else, so I'm not taking a big dive either way.

Today I removed the timing belt covers, crank pulley, and engine mount and installed a new belt (as close to aligned as I can without the crank/cam holding tool... I have purchased one and it's on the way)

Good news is cylinders 1,2, and 4 have good compression (~170 +/- 10 psi) but cylinder 3 is flat dead. I knew it I'd likely have some bent valves, and I've done a few backyard head pulls and head jobs before, but this will be my first Volvo. I guess I'm lucky it's only the one cylinder.

I have a couple of questions now. I have a copy of the VIDA software (and also VADIS) but I'm having trouble getting it to run on Windows 8. Do I just need to load up XP on an old computer and do it that way or is there some trick? VIDA opens but starts throwing errors after I type in the VIN and I can't actually look at any service info.

Second question: I'm going to begin the process of pulling the head today. Has anyone done this before? Anything major to watch out for?

Third and final (for now) question: it looks like the belt failure was likely caused by oil getting thrown out of the VVT gear and onto the belt. I'm comfortable doing a cam seal (since I'm removing them and the engine has over 100k I'll be replacing them) but I've never done a VVT seal. Any tips?

Thanks a ton guys, and I look forward to joining you on the road in a couple of weeks!

Jon

#2

#3

The big gotcha is the VVT gear itself. It mounts to the exhaust cam with one large bolt in the center and can be mounted in any orientation (360* movement). There are a couple ways to tackle this problem depending on how you fix the VVT leak.

If you plan to fix the leak by replacing the o-ring on the plunger then you do not have to remove the VVT gear at all. Just slip the cam seal off the other end of the cam after working it over the cam lobes. Since the VVT gear never moves the timing mark is still properly aligned.

If you plan on replacing the VVT gear then things get a bit more complicated. Now you need to purchase the Volvo cam holder tool. This tool aligns and holds both cams in their proper place for timing belt replacement. Now the VVT gear can be removed and replaced by lining up the timing mark on the outer ring with the plastic timing belt cover. The VVT gear bolt torque is about 85 lb/ft so the cam must be held tight and the timing mark watched carefully as it will tend to rotate the VVT gear.

The 3rd and most unpleasant method is to remove the VVT gear and THEN discover you do not have the cam holder tool and did not mark the VVT gear in relation to anything. This was my method and it took me 4 tries of taking things apart and making a crude cam holder tool before I got the timing close enough to stop the check engine light. Lesson learned.

If you plan to fix the leak by replacing the o-ring on the plunger then you do not have to remove the VVT gear at all. Just slip the cam seal off the other end of the cam after working it over the cam lobes. Since the VVT gear never moves the timing mark is still properly aligned.

If you plan on replacing the VVT gear then things get a bit more complicated. Now you need to purchase the Volvo cam holder tool. This tool aligns and holds both cams in their proper place for timing belt replacement. Now the VVT gear can be removed and replaced by lining up the timing mark on the outer ring with the plastic timing belt cover. The VVT gear bolt torque is about 85 lb/ft so the cam must be held tight and the timing mark watched carefully as it will tend to rotate the VVT gear.

The 3rd and most unpleasant method is to remove the VVT gear and THEN discover you do not have the cam holder tool and did not mark the VVT gear in relation to anything. This was my method and it took me 4 tries of taking things apart and making a crude cam holder tool before I got the timing close enough to stop the check engine light. Lesson learned.

#4

#5

here's a link to a post with a guide that I put toghether for changing the vvt, seals, etc. Hope it helps.

GUIDE: Replacing Cam Seals / Crank Seal / VVT Hub - Volvo Owners Club Forum

make sure you use the second link on page 2!

Here's another guide for an engine removal which I think might help too.

Cylinder Head Transplant B4204S Engine - Volvo Owners Club Forum

GUIDE: Replacing Cam Seals / Crank Seal / VVT Hub - Volvo Owners Club Forum

make sure you use the second link on page 2!

Here's another guide for an engine removal which I think might help too.

Cylinder Head Transplant B4204S Engine - Volvo Owners Club Forum

#6

Thanks a ton for the excellent photos and guides, guys! I really appreciate it. I've ordered the cam/crank alignment tool set (comes with the clamps to remove the valve cover) and I'll proceed once I get those.

One additional question: I don't have an appropriate socket to remove the strange seemingly Volvo specific reverse torx nuts and bolts on the VVT gear assembly itself. I'm sure I can get them off with a vice grip, but do you know if they are easily replaceable with normal metric bolts and nuts? I imagine my vice grips will shred them. I can pick up just about any size of corrosion resistant steel metric stuff at the local hardware store, I just am wondering if they're threaded funny as well.

Thanks so much! I'll update with pictures and such when I tear into it after all the tools are here.

One additional question: I don't have an appropriate socket to remove the strange seemingly Volvo specific reverse torx nuts and bolts on the VVT gear assembly itself. I'm sure I can get them off with a vice grip, but do you know if they are easily replaceable with normal metric bolts and nuts? I imagine my vice grips will shred them. I can pick up just about any size of corrosion resistant steel metric stuff at the local hardware store, I just am wondering if they're threaded funny as well.

Thanks so much! I'll update with pictures and such when I tear into it after all the tools are here.

#8

I have a small set of reverse torx sockets, and the only one that goes on it feels quite loose... loose enough that I'm concerned I'll round it off. The "points" (for lack of a better term) of the star on the Volvo nut are considerably rounder than torx stuff I'm used to seeing.

It might work. If I end up having to replace them after either the socket or my vice grips trashes them, I'll let you guys know if I'm able to find a suitable replacement. Thanks!

It might work. If I end up having to replace them after either the socket or my vice grips trashes them, I'll let you guys know if I'm able to find a suitable replacement. Thanks!

#9

I have a small set of reverse torx sockets, and the only one that goes on it feels quite loose... loose enough that I'm concerned I'll round it off. The "points" (for lack of a better term) of the star on the Volvo nut are considerably rounder than torx stuff I'm used to seeing.

It might work. If I end up having to replace them after either the socket or my vice grips trashes them, I'll let you guys know if I'm able to find a suitable replacement. Thanks!

It might work. If I end up having to replace them after either the socket or my vice grips trashes them, I'll let you guys know if I'm able to find a suitable replacement. Thanks!

The little piston is in fact just a hole plug. To fix it you'll need a metric o-ring 8.5 mm x 2 mm. That's 8.5 mm ID and 2 mm width (diameter of the cross-section).

I'm pretty confident a ghetto fix would also work fine. Without taking anything apart, clean up the piston area with spray carb cleaner and fill the depression around the piston with flowable silicone.

#10

UPDATE!

I finished pulling the head today. Both intake valves on cylinder 3 were bent, but the seats and guides look okay. Piston was marked minimally, not even enough to sand off a burr to avoid a hotspot. I already ordered 2 new intake and 2 new exhaust valves, so I'm set there.

Since I've pulled the head anyway, I'm gonna lap all the valves and seats since the engine has over 100k. There is significant carbon buildup on the exhaust side. It's gonna be a pain to remove, but while I've got the head off I might as well do a full top end job (well, as close as one can do in his back yard and living room).

But GOOD HEAVENS this head is gunky. The oil passages are pretty sludge filled. Any suggestions on a product to soak it in to try to free some of this stuff?

Thanks again, folks!

Jon

EDIT: As I'm a bachelor, I think I'm gonna run it through the dishwasher once on each side and see what we come out with. Wish me luck!

I finished pulling the head today. Both intake valves on cylinder 3 were bent, but the seats and guides look okay. Piston was marked minimally, not even enough to sand off a burr to avoid a hotspot. I already ordered 2 new intake and 2 new exhaust valves, so I'm set there.

Since I've pulled the head anyway, I'm gonna lap all the valves and seats since the engine has over 100k. There is significant carbon buildup on the exhaust side. It's gonna be a pain to remove, but while I've got the head off I might as well do a full top end job (well, as close as one can do in his back yard and living room).

But GOOD HEAVENS this head is gunky. The oil passages are pretty sludge filled. Any suggestions on a product to soak it in to try to free some of this stuff?

Thanks again, folks!

Jon

EDIT: As I'm a bachelor, I think I'm gonna run it through the dishwasher once on each side and see what we come out with. Wish me luck!

Last edited by utapesgeometriam; 09-12-2014 at 12:03 AM. Reason: Additional info

#11

Hmmmm, instead of putting it in the dishwasher I would be tempted to bring it over to my local transmission/engine specialist. Pretty sure that a simple cleaning would not be expensive plus they would have equipment that would do a great job without having to be concerned about corrosion, stuff left behind, etc.

#12

Well, I'd be more wary to put the head of a car I cared about in the dishwasher. It actually worked okay... got out a fair amount of the gunk, but mostly just off of surfaces rather than in the small passages. I left it soaking in mineral spirits this morning to remove any leftover soap, etc.

I'm going to call around to machine shops in the area and see how much it'd cost to have it cleaned.

Another question: Which valve compressor tool have you folks used to remove and install valves? I have a small claw tool that works for other engines, but I had to rent a larger c-clamp style one to get to the recesses in this one. I was able to remove the valves fine (yes, I removed valves, springs, shims, and seals prior to the dishwasher adventure) but I don't think I'll have enough room to put the keepers back on when I reassemble.

Thanks a ton, especially for the words of caution. I really do appreciate it.

EDIT: As I promised pictures, attached is a picture of the bent valves. Both intake valves on cylinder 3 were whacked.

I'm going to call around to machine shops in the area and see how much it'd cost to have it cleaned.

Another question: Which valve compressor tool have you folks used to remove and install valves? I have a small claw tool that works for other engines, but I had to rent a larger c-clamp style one to get to the recesses in this one. I was able to remove the valves fine (yes, I removed valves, springs, shims, and seals prior to the dishwasher adventure) but I don't think I'll have enough room to put the keepers back on when I reassemble.

Thanks a ton, especially for the words of caution. I really do appreciate it.

EDIT: As I promised pictures, attached is a picture of the bent valves. Both intake valves on cylinder 3 were whacked.

Last edited by utapesgeometriam; 09-12-2014 at 09:05 AM. Reason: Added picture

#13

I called around and found a machine shop in town that would clean the head (paying special attention to the clogged oil passages) and check for warping for $20. I dropped it off a few minutes ago. I imagine it'll be a few days since it's low priority work for them but I don't mind since I'm in no rush to finish the project.

But this leads me to a new series of performance upgrade questions:

I'm in just under $1000 for the car, tools and parts to make it run stock at this point. Book value is around $2600 in my area for "good" condition. I don't mind spending up to around another $1000 for performance parts (saving that $600 for the approximate cost of a tune if I decide to do performance mods) so what would you guys recommend that I do once I get it up and running (after completing stage zero stuff, of course)?

My thoughts are the following:

K&N high flow filter - $50. It looks like the stock intake does a decent job of putting cold air in the engine. Anybody got an aftermarket cold air intake that works well?

Exhaust overhaul - Mandrel bent 3" down pipe, 2.5" cat back and muffler - ~$200-$300 (a buddy of mine owns a muffler shop, so he can do it cheap for me)

14T turbo upgrade - I see ones that appear in good condition go for ~$200 on E-bay. Anybody done that? If so, did you also do a front mounted intercooler?

550cc "red" injector upgrade - set of Bosch EV14s goes for around $150

That would take me up to around $750 in performance parts. Any other thoughts/recommendations? Feel free to throw crazy ideas out there.

Thanks again, guys.

But this leads me to a new series of performance upgrade questions:

I'm in just under $1000 for the car, tools and parts to make it run stock at this point. Book value is around $2600 in my area for "good" condition. I don't mind spending up to around another $1000 for performance parts (saving that $600 for the approximate cost of a tune if I decide to do performance mods) so what would you guys recommend that I do once I get it up and running (after completing stage zero stuff, of course)?

My thoughts are the following:

K&N high flow filter - $50. It looks like the stock intake does a decent job of putting cold air in the engine. Anybody got an aftermarket cold air intake that works well?

Exhaust overhaul - Mandrel bent 3" down pipe, 2.5" cat back and muffler - ~$200-$300 (a buddy of mine owns a muffler shop, so he can do it cheap for me)

14T turbo upgrade - I see ones that appear in good condition go for ~$200 on E-bay. Anybody done that? If so, did you also do a front mounted intercooler?

550cc "red" injector upgrade - set of Bosch EV14s goes for around $150

That would take me up to around $750 in performance parts. Any other thoughts/recommendations? Feel free to throw crazy ideas out there.

Thanks again, guys.

#14

It has an air/air intercooler already. Do you mean a bigger, more efficient one maybe? (Not that I know where to find one)

I've heard the 14T turbo is a nice bump in power. A manual boost controller would be needed for higher boost. This will call for tuning to keep the check engine light off for overboost. You sure you want to go down this road? It can get pricey quick.

I've heard the 14T turbo is a nice bump in power. A manual boost controller would be needed for higher boost. This will call for tuning to keep the check engine light off for overboost. You sure you want to go down this road? It can get pricey quick.

#15

Sorry, should have said FMIC upgrade. I figure that the stock intercooler would be less efficient at the higher psi/cfm that the 14T would put out, as it was made for stock boost with the 12T.

Regarding an MBC, is the wastegate controlled by the ECU, or does it open at a set boost level mechanically? If I do any performance upgrades I'll be getting a tune, and the literature I could find seemed to indicate that a proper tune can raise boost levels without mechanical intervention. UPsolute tuning was actually very reasonably priced compared to what I have seen spent on other ECU tunes.

Regarding the surety of my resolve... heck no I'm not sure. At this point it's all hypothetical spitballing. It's entirely possible that once I get the head back from the machine shop, lap in the valves and put everything back together that the bottom end is shot or the tranny is near end of life.

I'd also be lying if I said the S40 was my first choice in performance mod platform, but

it has a couple of advantages: I have one that I got for cheap and it looks like parts are not as ridiculously priced as I'd assumed they'd be. Most of the labor I'm comfortable doing or farming out to more capable friends for beer.

I'm not looking for insane gains, but it looks like it'd be reasonable to expect a 40-50hp increase with the mods I've considered so far. And since I'm an unmarried computer engineer in his late 20's... it's already well established that I have more money than sense.

I do appreciate the reality check though. You're good people, Hudini.

Regarding an MBC, is the wastegate controlled by the ECU, or does it open at a set boost level mechanically? If I do any performance upgrades I'll be getting a tune, and the literature I could find seemed to indicate that a proper tune can raise boost levels without mechanical intervention. UPsolute tuning was actually very reasonably priced compared to what I have seen spent on other ECU tunes.

Regarding the surety of my resolve... heck no I'm not sure. At this point it's all hypothetical spitballing. It's entirely possible that once I get the head back from the machine shop, lap in the valves and put everything back together that the bottom end is shot or the tranny is near end of life.

I'd also be lying if I said the S40 was my first choice in performance mod platform, but

it has a couple of advantages: I have one that I got for cheap and it looks like parts are not as ridiculously priced as I'd assumed they'd be. Most of the labor I'm comfortable doing or farming out to more capable friends for beer.

I'm not looking for insane gains, but it looks like it'd be reasonable to expect a 40-50hp increase with the mods I've considered so far. And since I'm an unmarried computer engineer in his late 20's... it's already well established that I have more money than sense.

I do appreciate the reality check though. You're good people, Hudini.

#16

I'm just a crazy DIY shade tree parts changer. I bought a cheap 1986 Pontiac Fiero GT then installed a bigger 3.4L engine out of a 1995 Camaro then added a T3 turbo from a 1983 Ford Turbo Coupe. I bought a Moates chip emulator and swapped computers and added an air/water intercooler and oh hell I've spent a bunch of money and it's still an old car. I'm already down that road I mentioned above. It's still fun though.

#17

I got the head back from the machine shop this morning. It was not warped (thank goodness I took it slow and loosened the head bolts in 4 stages) and all in all cleaned up pretty well. Tonight I plan to lap the valves (including the new valves) back in and reassemble the seals and valve spring assemblies. Hopefully by the weekend I'll have it reassembled and road tested. Attached are a couple of pictures of the head post cleaning. I wish I'd taken some pre cleaning pictures, but just imagine nasty brown sludge and carbon everywhere. It still isn't perfect, and I'm going to remove the remainder of the gasket material from the head to ensure a good fit.

Also, as a bonus, while I was picking up the head the owner of the shop came out with his computer under his arm and we got to talking about it. I'm a computer engineer by trade and found out that his shop computer with all invoicing on it had died and he was taking it to a friend to try to recover data. If the friend fails he's gonna give me a call and we'll work out a trade of services and I'll recover the data. So what should I ask for? Port and polish? Cam grinding? Likely I'll just bank the favor for a rainy day, but I've found it's good to have people with skills who owe you favors...

Also, as a bonus, while I was picking up the head the owner of the shop came out with his computer under his arm and we got to talking about it. I'm a computer engineer by trade and found out that his shop computer with all invoicing on it had died and he was taking it to a friend to try to recover data. If the friend fails he's gonna give me a call and we'll work out a trade of services and I'll recover the data. So what should I ask for? Port and polish? Cam grinding? Likely I'll just bank the favor for a rainy day, but I've found it's good to have people with skills who owe you favors...

#18

#19

Since my last post, I have lapped in the 12 usable old valves and the 4 new valves. I also installed new valve seals and reassembled the valve spring washer/retainer/collet assemblies. At first I thought lapping in valves was strangely zen, but around hour three of rubbing my hands together like a mad man it became much less so. I got out all pitting (overall very minor, mostly isolated to exhaust side) and discovered that I had two very slightly bent exhaust valves from cylinder 4. Good thing I ordered two intake and two exhaust valves, right?

Because the valves are recessed into the head pretty far, I ended up buying a different valve spring compressor. If anyone is wondering what will work on this (or I assume any of the Volvo modular engines) the OHC 4572 Large Valve Spring Compressor does the trick with plenty of room to spare, and at $50 is a solid buy. I'd also like to take a moment to recommend the Tekton brand of torque wrenches. I don't use mine too often, but they are solidly constructed and very affordable at around $40 a piece for the size/torque range of your choice.

I did a poor man's leak test (kerosene in the intake and exhaust to check for leaks) without a single drip in an hour of sitting. Then I cleaned the mating surfaces of the head and this evening after work torqued down the head bolts to spec. Man, is it ever easier to TIGHTEN head bolts than it is to LOOSEN them!

I also found a 14T turbo in a Pick-A-Part around here that I'm gonna go pull tomorrow. They only wanted $75 for it, and they claim that the car only had ~60k on the odo when it got in the accident that landed it in the scrap yard. Also ordered a set of Bosch EV14's (550cc) at $150. My understanding is that both of these will go on and work with the stock ECU, albeit with little to no gain without a tune. That's fine, I'll save my pennies and get a tune once I have it all back together and road tested.

Thanks again to everyone who has helped to this point! I'll update tomorrow evening with progress.

Attached is a pic of the head on the engine. Good heavens does it feel good to have the hard work behind me! (Well hopefully the hard work is behind me...)

Because the valves are recessed into the head pretty far, I ended up buying a different valve spring compressor. If anyone is wondering what will work on this (or I assume any of the Volvo modular engines) the OHC 4572 Large Valve Spring Compressor does the trick with plenty of room to spare, and at $50 is a solid buy. I'd also like to take a moment to recommend the Tekton brand of torque wrenches. I don't use mine too often, but they are solidly constructed and very affordable at around $40 a piece for the size/torque range of your choice.

I did a poor man's leak test (kerosene in the intake and exhaust to check for leaks) without a single drip in an hour of sitting. Then I cleaned the mating surfaces of the head and this evening after work torqued down the head bolts to spec. Man, is it ever easier to TIGHTEN head bolts than it is to LOOSEN them!

I also found a 14T turbo in a Pick-A-Part around here that I'm gonna go pull tomorrow. They only wanted $75 for it, and they claim that the car only had ~60k on the odo when it got in the accident that landed it in the scrap yard. Also ordered a set of Bosch EV14's (550cc) at $150. My understanding is that both of these will go on and work with the stock ECU, albeit with little to no gain without a tune. That's fine, I'll save my pennies and get a tune once I have it all back together and road tested.

Thanks again to everyone who has helped to this point! I'll update tomorrow evening with progress.

Attached is a pic of the head on the engine. Good heavens does it feel good to have the hard work behind me! (Well hopefully the hard work is behind me...)

#20

Just a quick update...

IT RUNS!

Compression is good at 180 +/- 10psi in all cylinders. I still have to trace down a couple of small leaks (coolant hoses, etc) and bolt on the exhaust manifold. (No, I didn't run it under load or for any appreciable amount of time without an exhaust manifold.) I just figured since it's such a PITA to remove and add, I'd wait until the new turbo comes in on Monday or Tuesday and do it all then.

The only code that appeared during the ~30 seconds I let it idle was a 0300 Random misfire code, which I suspect will be remedied when I do plugs/wires/coils next week.

Thanks again, guys. This has been quite an adventure...

IT RUNS!

Compression is good at 180 +/- 10psi in all cylinders. I still have to trace down a couple of small leaks (coolant hoses, etc) and bolt on the exhaust manifold. (No, I didn't run it under load or for any appreciable amount of time without an exhaust manifold.) I just figured since it's such a PITA to remove and add, I'd wait until the new turbo comes in on Monday or Tuesday and do it all then.

The only code that appeared during the ~30 seconds I let it idle was a 0300 Random misfire code, which I suspect will be remedied when I do plugs/wires/coils next week.

Thanks again, guys. This has been quite an adventure...

Last edited by utapesgeometriam; 09-20-2014 at 07:59 PM. Reason: Words and such