1996 Volvo 960 Cam Timing

#1

Folks, I need a little help here.

I had to replace the head gasket on my 960, and I went ahead and had the head serviced at a very reliable head shop. I got the lower head bolted back onto the block, and this evening I put the camshafts and upper head (aka valve cover/upper cam journals) back on. I used a homemade metal plate and a magnetic angle finder on the back of the camshafts to line them up properly before installing the cam sprockets, and found TDC of #1 with a rod in the sparkplug hole and a dial indicator.

Here's the problem: with the camshaft sprockets lined up properly with their marks (done so with the crankshaft backed off a couple of teeth just in case), I cannot bring the crankshaft to TDC without running into an exhaust valve. I've tried approaching it from both rotational directions of the crank, but no matter what I have to move the exhaust cam significantly off time to rotate the crank into position.

I've got a couple of questions: First, has anyone seen this happen before? Second, in all of the disassembly/reassembly, if I accidentally swapped the intake and exhaust cams, how would I be able to tell visually? Are there markings on either end so that I don't have to remove the upper head assy to tell? My manual is woefully short on information here.

Thanks for the help.

--dan

I had to replace the head gasket on my 960, and I went ahead and had the head serviced at a very reliable head shop. I got the lower head bolted back onto the block, and this evening I put the camshafts and upper head (aka valve cover/upper cam journals) back on. I used a homemade metal plate and a magnetic angle finder on the back of the camshafts to line them up properly before installing the cam sprockets, and found TDC of #1 with a rod in the sparkplug hole and a dial indicator.

Here's the problem: with the camshaft sprockets lined up properly with their marks (done so with the crankshaft backed off a couple of teeth just in case), I cannot bring the crankshaft to TDC without running into an exhaust valve. I've tried approaching it from both rotational directions of the crank, but no matter what I have to move the exhaust cam significantly off time to rotate the crank into position.

I've got a couple of questions: First, has anyone seen this happen before? Second, in all of the disassembly/reassembly, if I accidentally swapped the intake and exhaust cams, how would I be able to tell visually? Are there markings on either end so that I don't have to remove the upper head assy to tell? My manual is woefully short on information here.

Thanks for the help.

--dan

#2

For a bit more information, I recently purchased the car and when I was removing the head, I noticed that the two cam sprockets were different from each other. The exhaust has trapezoidal holes and a rubber damper assy attached to the back of it, the intake has circular holes with no damper. There is evidence that the previous owner had the belt changed, and maybe had the head off.

#3

Okay, after knocking heads with a couple of car buddies of mine, something occurred to me: In the past with other cars, I've always done cam timing with the crankshaft referenced to TDC#1. What if the Volvo doesn't use TDC#1 as the alignment point? Since I had always assumed that, I started looking for the crank timing mark when I was close to TDC, not thinking it might be on the other side of the sprocket. When I got home from work I alternately worked the crankshaft and cams around until I found the notch in the crank timing sprocket.

Both of my manuals never made any reference to TDC#1, just to finding the marks and aligning them. Gross Conceptual Error on my part. Looks like the beastie's going back together sooner than I thought. I just hope someone can learn from my experience. Thanks for providing this forum to share this stuff!

--dan

Both of my manuals never made any reference to TDC#1, just to finding the marks and aligning them. Gross Conceptual Error on my part. Looks like the beastie's going back together sooner than I thought. I just hope someone can learn from my experience. Thanks for providing this forum to share this stuff!

--dan

#4

they dont use TDC to set the cams. line the marks up. you can put the top cam cover back on while setting the cams and bolting the valve cover down to make sure everything is lined up.

be carefull with those valve cover bolts. they are torqued to something like 13lbs and they strip VERY easily.

either clamp the cover down or very gently use the bolts to pull it down.

be carefull with those valve cover bolts. they are torqued to something like 13lbs and they strip VERY easily.

either clamp the cover down or very gently use the bolts to pull it down.

#5

Here is what I did to change the timing belt. Not sure if any of this information will help or not.

Timing belt replacement instructions on a 1997 Volvo 960

Timing belt replacement instructions on a 1997 Volvo 960

#6

Thanks, fellas, for your input. Engine is up and running very nicely. About the only thing I have to work on at this point is some combustion knock during part and full throttle accels. The knock sensors are attached but not sure why they're not catching it. It's a minor annoyance I'll figure out soon. Otherwise the car runs great and I've managed 25mpg highway so far with the inline 6. Love it.

#7

Are you using 91+ octane? That is what Volvo recommends. When I was pushing my 960 I was getting 25 mpg around town and as much as 31 on the highway (usually 29).

https://volvoforums.com/forum/audio-...74/#post263989

You can also check the fuel economy link in the 850 section.

https://volvoforums.com/forum/audio-...74/#post263989

You can also check the fuel economy link in the 850 section.

#8

Thanks, fellas, for your input. Engine is up and running very nicely. About the only thing I have to work on at this point is some combustion knock during part and full throttle accels. The knock sensors are attached but not sure why they're not catching it. It's a minor annoyance I'll figure out soon. Otherwise the car runs great and I've managed 25mpg highway so far with the inline 6. Love it.

#9

i never used 91 in my car. never had any knock.

i am concerned about the knock too. originally i was thinking cam timing (not that the valves are hitting). someone advanced my cams by 15 degrees in my 911. took me quite a while to figure it out, although i was suspicious of it all along. dont put this at the top of your list, but keep it in mind. i had spark knock like you. i could not floor it or push it too hard. kept me from speeding for quite a while though. .

.

the cam gear in my 95 had some adjustment where the gear bolted to the cam. its not much and i dont know if it would cause any problems if not set correctly.

check for vacuum leaks, could be too lean.

i am concerned about the knock too. originally i was thinking cam timing (not that the valves are hitting). someone advanced my cams by 15 degrees in my 911. took me quite a while to figure it out, although i was suspicious of it all along. dont put this at the top of your list, but keep it in mind. i had spark knock like you. i could not floor it or push it too hard. kept me from speeding for quite a while though.

.

.the cam gear in my 95 had some adjustment where the gear bolted to the cam. its not much and i dont know if it would cause any problems if not set correctly.

check for vacuum leaks, could be too lean.

#10

For the first three tanks after I bought the vehicle, I ran 93 octane in it, and it had tip-in knock with all of them. As you can see from my earlier posts, I ended up taking the head off and having it reconditioned (before those three tanks of fuel), so everything up top is new. All three of you make excellent points, and they are all potential concerns that I'll need to look into. A couple of questions regarding your points:

1. If I were using lower octane fuel (which I probably will if I can get away with it), and if the knock sensor electronics were functioning correctly, wouldn't the system just retard the timing until the knock went away? Or is there only so much authority it has?

2. The cam timing is a distinct possibility, with the cam position sensor on the back of the exhaust cam. The alignment slot on the back of the camshaft is hard to see with it back in the engine, so I made an alignment tool out of some 1/8" bar stock and did the best I could... Does anyone have a feel for how much that could be off before it causes a problem? More importantly, since this is a coil over plug engine, is there any way to check the timing with a timing light? If so, how? And what should base idle timing be?

3. When I was reinstalling the head, I replaced the vacuum hoses that were obviously loose or cracked. If I had a vacuum leak, causing lean running, wouldn't it tend to idle high? I have noticed that the cruise control is fairly slow to respond to a set command, and the climate controls also, leading me to think there is some value to just going through and replacing the rest of the hoses, so thanks for that.

1. If I were using lower octane fuel (which I probably will if I can get away with it), and if the knock sensor electronics were functioning correctly, wouldn't the system just retard the timing until the knock went away? Or is there only so much authority it has?

2. The cam timing is a distinct possibility, with the cam position sensor on the back of the exhaust cam. The alignment slot on the back of the camshaft is hard to see with it back in the engine, so I made an alignment tool out of some 1/8" bar stock and did the best I could... Does anyone have a feel for how much that could be off before it causes a problem? More importantly, since this is a coil over plug engine, is there any way to check the timing with a timing light? If so, how? And what should base idle timing be?

3. When I was reinstalling the head, I replaced the vacuum hoses that were obviously loose or cracked. If I had a vacuum leak, causing lean running, wouldn't it tend to idle high? I have noticed that the cruise control is fairly slow to respond to a set command, and the climate controls also, leading me to think there is some value to just going through and replacing the rest of the hoses, so thanks for that.

#11

The cam timing is a distinct possibility, with the cam position sensor on the back of the exhaust cam. The alignment slot on the back of the camshaft is hard to see with it back in the engine, so I made an alignment tool out of some 1/8" bar stock and did the best I could... Does anyone have a feel for how much that could be off before it causes a problem? More importantly, since this is a coil over plug engine, is there any way to check the timing with a timing light? If so, how? And what should base idle timing be?

When I was reinstalling the head, I replaced the vacuum hoses that were obviously loose or cracked. If I had a vacuum leak, causing lean running, wouldn't it tend to idle high? I have noticed that the cruise control is fairly slow to respond to a set command, and the climate controls also, leading me to think there is some value to just going through and replacing the rest of the hoses, so thanks for that.

Last edited by Henry10; 07-20-2012 at 10:37 PM.

#12

I will grab my vacuum gauge and go through that link. Thanks a lot for that, it will be very instructive.

About the cam timing, I agree that it's normally all done from the front, except when the cam sprockets are removed during the head disassembly, which is the case here. The three bolt holes on each cam sprocket are slotted to allow for adjustment, but the reference for installing them is a slot cut into the back of the camshaft. So, when reinstalling the sprocket, the camshaft must be reinstalled in the head and this slot lined up with the machined face between what Volvo calls the upper and lower head (what's normally considered the cam cover and head). It's pretty difficult to see this slot and set it to the reference line without a special tool which I don't own. So I made one. Anyway, once you get this slot lined up and the cam belt installed with the cam sprockets loosely bolted to the cams, you can tighten the cam sprocket bolts.

Thinking about it, I need to go back and check the slot alignment with all the crank/cam sprockets lined up with their marks. I'll do it this afternoon when I go through the vacuum checks in the link you provided, and give an update on what I find. By the way, it would be interesting to know if the scan tool is using the crank position or cam position sensor as a reference when it checks timing. If it's the cam and I've got the sprocket misadjusted, then the scantool won't know it. I'll drop by Autozone and borrow their tool and see. Thanks again for all the suggestions!

About the cam timing, I agree that it's normally all done from the front, except when the cam sprockets are removed during the head disassembly, which is the case here. The three bolt holes on each cam sprocket are slotted to allow for adjustment, but the reference for installing them is a slot cut into the back of the camshaft. So, when reinstalling the sprocket, the camshaft must be reinstalled in the head and this slot lined up with the machined face between what Volvo calls the upper and lower head (what's normally considered the cam cover and head). It's pretty difficult to see this slot and set it to the reference line without a special tool which I don't own. So I made one. Anyway, once you get this slot lined up and the cam belt installed with the cam sprockets loosely bolted to the cams, you can tighten the cam sprocket bolts.

Thinking about it, I need to go back and check the slot alignment with all the crank/cam sprockets lined up with their marks. I'll do it this afternoon when I go through the vacuum checks in the link you provided, and give an update on what I find. By the way, it would be interesting to know if the scan tool is using the crank position or cam position sensor as a reference when it checks timing. If it's the cam and I've got the sprocket misadjusted, then the scantool won't know it. I'll drop by Autozone and borrow their tool and see. Thanks again for all the suggestions!

#14

By the way, it would be interesting to know if the scan tool is using the crank position or cam position sensor as a reference when it checks timing. If it's the cam and I've got the sprocket misadjusted, then the scantool won't know it. I'll drop by Autozone and borrow their tool and see. Thanks again for all the suggestions!

I can read my timing with my laptop, OBDII software and a dongle connected to OBD port.

#15

Henry, I don't know if you're referring to a different engine, but I'm pretty sure it would be impossible to take the head off the 2.9L inline six without removing the camshafts. This engine is like the inline 5's in that the cam cover is also the upper bearing assembly for the camshafts. There are 32 bolts that hold this onto the head, and you cannot access the head bolts without removing the cam cover. Then, once the the cover is removed, it's pretty much a given that the cams will come out because (a) a couple of the head bolts are under or very close to the cams, and (b) the cams pop up anyway due to valve spring pressure when the upper bearing assembly is removed.

Now, I did reinstall the cams by bungee cording them to the cam cover and lowering them onto the head, so I suppose I could have taken them out without removing the sprockets from the cams, keeping them at least correctly timed together. Unfortunately, the manual I had said to take the sprockets off prior to removing the cam cover. Live and learn.

Now, I did reinstall the cams by bungee cording them to the cam cover and lowering them onto the head, so I suppose I could have taken them out without removing the sprockets from the cams, keeping them at least correctly timed together. Unfortunately, the manual I had said to take the sprockets off prior to removing the cam cover. Live and learn.

#17

That's what I thought. I've seen the head installation toolkit on various websites that has all of the specialty tools for holding and aligning the cams as well as drawing the cam cover down to the head without stressing the camshafts. As I have an 850 turbo that needs a head gasket, it looks like it will be worth the investment in this toolkit for the long haul, as I'm pretty much converting my fleet over to Volvos right now (wife and five driving-age kids translates into "fleet").

I've also seen some OBD dongles/software on the net and am finding that I'm going to need this for the cars I'm purchasing now (to date I've been a diehard pre-1995 car groupie). Do you have a particular tool that you can recommend?

I've also seen some OBD dongles/software on the net and am finding that I'm going to need this for the cars I'm purchasing now (to date I've been a diehard pre-1995 car groupie). Do you have a particular tool that you can recommend?

#18

You can search here or 850 Forum for choices of OBD tools. I have bought a few from Scantool.net. I have a set from AutoEnginuity as well in my shop.

I also keep a dongle in every car, in case I need to read and erase codes on the go. I think I paid like $ 20 or $ 30 each. You get a dongle (OBD / USB connector) and download software for free, depending on deal/vendor.

Keep in mind, these are generic readers and will not read some Volvo's proprietary codes (ABS or SRS for example). You can pull a lot more codes from the push-button on 94/95 Volvos than newer Volvos (no push-button) with generic tools.

I built a DIY tool (about $ 5 in parts) to pull proprietary codes from 96-later Volvos. I posted here some time ago.

I also keep a dongle in every car, in case I need to read and erase codes on the go. I think I paid like $ 20 or $ 30 each. You get a dongle (OBD / USB connector) and download software for free, depending on deal/vendor.

Keep in mind, these are generic readers and will not read some Volvo's proprietary codes (ABS or SRS for example). You can pull a lot more codes from the push-button on 94/95 Volvos than newer Volvos (no push-button) with generic tools.

I built a DIY tool (about $ 5 in parts) to pull proprietary codes from 96-later Volvos. I posted here some time ago.

#19

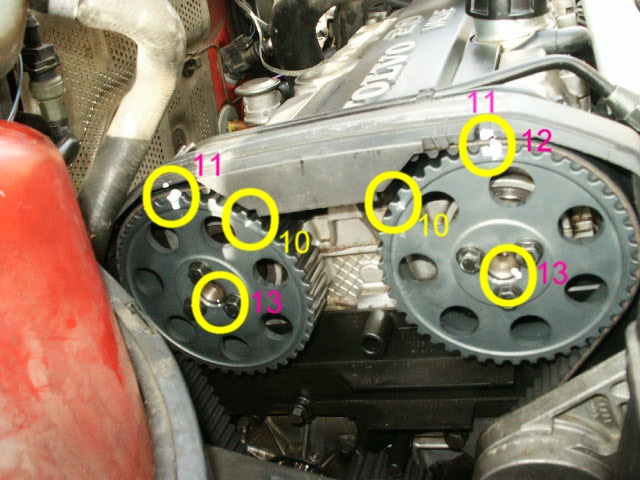

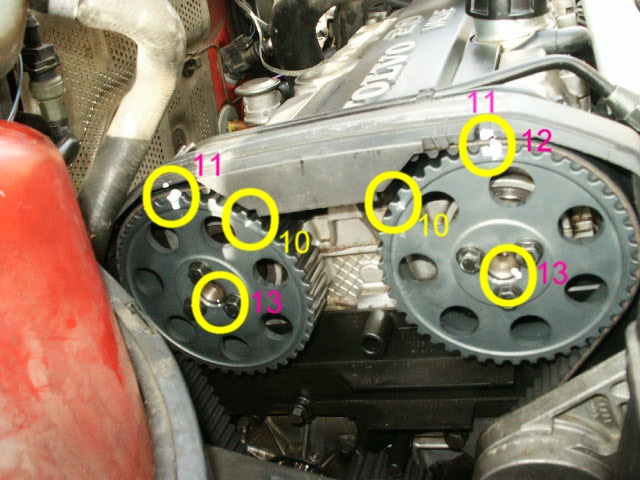

Here's a picture of all the marks I put on the cam sprockets and cam shaft when I pulled the sprockets from the cams, while doing the front cam seals.

Yea, when you lock the cams to the cam cover they will stay put while pulling the head. When I did the head on our S70 a few weeks ago, I did not pull the sprockets and set the cam cover on top of the cams, then set the timing belt cover on top of that, then used a stiff piece of card board to zip tie the cams in place before I set them on the head. Then I drew the cover down on to the head with the screws in the slow process that Tracy explained. Took a few minutes but it drew down nicely. The anaerobic sealant stays wet forever, over a week in the pan I used so time is no issue. I think the best thing is to leave the sprockets attached to the cams so you don't have to worry about the adjustment in the screw holes. Some people don't think you should because you run a risk of pinching the cam seals in the head but I did not worry about that. Lots of marks is the key.

Yea, when you lock the cams to the cam cover they will stay put while pulling the head. When I did the head on our S70 a few weeks ago, I did not pull the sprockets and set the cam cover on top of the cams, then set the timing belt cover on top of that, then used a stiff piece of card board to zip tie the cams in place before I set them on the head. Then I drew the cover down on to the head with the screws in the slow process that Tracy explained. Took a few minutes but it drew down nicely. The anaerobic sealant stays wet forever, over a week in the pan I used so time is no issue. I think the best thing is to leave the sprockets attached to the cams so you don't have to worry about the adjustment in the screw holes. Some people don't think you should because you run a risk of pinching the cam seals in the head but I did not worry about that. Lots of marks is the key.

#20

I took the sprockets off too when I did the head last year on my '98 I-6. Remember, cam for I-6 is longer and everything is heavier. Just like fixing the odometer -- I would rather take the whole dash apart, than force the panel from a mouse-hole. Of course, that leaves me with a long list of knick-knacks I break during the process. I am damn good at breaking and destroying things.

Like rspi said, marking is key, plus having the right tools saves a lot of time and aggravation.

Job looks easier on I-5, although I never did a 5. I crashed it too soon.

Like rspi said, marking is key, plus having the right tools saves a lot of time and aggravation.

Job looks easier on I-5, although I never did a 5. I crashed it too soon.