A/C cycling way too much

#1

OK, I've been chasing a less-than-perfect a/c system for a while, and think I've got it narrowed down... but want to tap into the collective wisdom of the Volvo universe and see if anyone else thinks I'm on the right (or wrong...) track.

Previously, my a/c compressor would cycle on and off as the pressure approached 250psi on the high side (I think that translates to about 1800kpa). I tried reducing the pressure, and sure enough the cycling finally stopped, but the a/c outlet temperature was nowhere near adequate (especially for the 110+ degree Arizona summers). I topped off the system with DuraCool (a non-polluting, non-freon substitute that I use for my older cars that are set up for R12, but that can be used in an R134a system). The advantage of this stuff is that it reduces the system pressure (and that it doesn't deplete the ozone, etc.). Now the high pressure is topping out around 200psi (1400kpa?), but the cycling continues... though the outlet temperature is a lot better, but still only down to about 55 degrees F (13C).

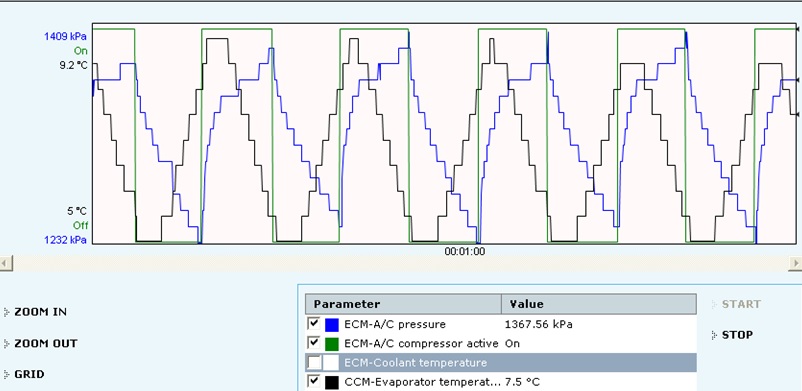

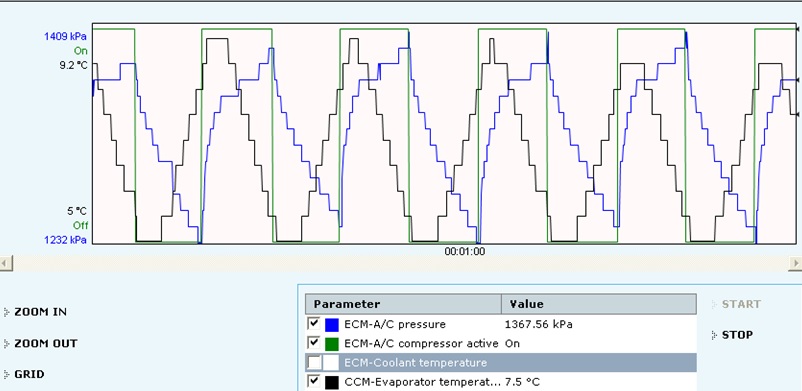

My Vida/Dice unit supplied me with this information:

I think this is telling me that it's not the pressure causing the cycling (at least not any longer), but the evaporator temperature getting too low. It's consistently cutting off the compressor when the evaporator temperature hits about 4.5 degree C (40 degrees F). Since my outlet temperature is still way above that (and too high) my guess is that the temperature sensor for the evaporator is off - or there's some sort of blockage that's keeping the full airflow to get to my vents (trapping too much "cool" in the evaporator).

Anyone else gone through this before?

Previously, my a/c compressor would cycle on and off as the pressure approached 250psi on the high side (I think that translates to about 1800kpa). I tried reducing the pressure, and sure enough the cycling finally stopped, but the a/c outlet temperature was nowhere near adequate (especially for the 110+ degree Arizona summers). I topped off the system with DuraCool (a non-polluting, non-freon substitute that I use for my older cars that are set up for R12, but that can be used in an R134a system). The advantage of this stuff is that it reduces the system pressure (and that it doesn't deplete the ozone, etc.). Now the high pressure is topping out around 200psi (1400kpa?), but the cycling continues... though the outlet temperature is a lot better, but still only down to about 55 degrees F (13C).

My Vida/Dice unit supplied me with this information:

I think this is telling me that it's not the pressure causing the cycling (at least not any longer), but the evaporator temperature getting too low. It's consistently cutting off the compressor when the evaporator temperature hits about 4.5 degree C (40 degrees F). Since my outlet temperature is still way above that (and too high) my guess is that the temperature sensor for the evaporator is off - or there's some sort of blockage that's keeping the full airflow to get to my vents (trapping too much "cool" in the evaporator).

Anyone else gone through this before?

#2

OK, so I answer a lot of my own posts... ;-)

I was knocking around on the S60 forum, and saw a reference to where the temperature sensor is, and how easy it is to get to. You just have to drop the panel under the driver's side dash (the one that includes the OBD port cover). This takes about 15 seconds on my car because the previous owner lost the two (unnecessary) screws. The temperature sensor is easily accessible once you're laying in the footwell looking up.

So I just pulled the sensor out of the airbox and left it hanging down by the accelerator pedal, and re-ran my test (with the evaporator sensor now reading a much higher cabin temperature rather than the cooler airbox temperature). Now the compressor stays engaged 100% and the outlet air temperature got down to 35 degrees F (2C). I still can't be entirely certain that the problem isn't some sort of obstruction, but wow do the vents blow cold now... I guess I'll order a new temperature sensor, though I'm guessing it would be OK to just leave it hanging out for the rest of the Arizona summer (colder is better).

Also, I checked the comparison between the cabin air temperature and the evaporator temperature, and they were about 3 degrees C (5 degrees F) apart (evaporator reading lower), which is probably enough to cause a problem. This was after the car had been sitting long enough that any residual "cool" in the airbox would have gone away.

Hope this helps someone else - if your A/C compressor is cycling on and off, this is a VERY easy test to see if it's because of a cheap and easy to replace temperature sensor.

I was knocking around on the S60 forum, and saw a reference to where the temperature sensor is, and how easy it is to get to. You just have to drop the panel under the driver's side dash (the one that includes the OBD port cover). This takes about 15 seconds on my car because the previous owner lost the two (unnecessary) screws. The temperature sensor is easily accessible once you're laying in the footwell looking up.

So I just pulled the sensor out of the airbox and left it hanging down by the accelerator pedal, and re-ran my test (with the evaporator sensor now reading a much higher cabin temperature rather than the cooler airbox temperature). Now the compressor stays engaged 100% and the outlet air temperature got down to 35 degrees F (2C). I still can't be entirely certain that the problem isn't some sort of obstruction, but wow do the vents blow cold now... I guess I'll order a new temperature sensor, though I'm guessing it would be OK to just leave it hanging out for the rest of the Arizona summer (colder is better).

Also, I checked the comparison between the cabin air temperature and the evaporator temperature, and they were about 3 degrees C (5 degrees F) apart (evaporator reading lower), which is probably enough to cause a problem. This was after the car had been sitting long enough that any residual "cool" in the airbox would have gone away.

Hope this helps someone else - if your A/C compressor is cycling on and off, this is a VERY easy test to see if it's because of a cheap and easy to replace temperature sensor.

#3

First and foremost - your system was designed to use R-134a. I'd recommend you use it. See here for some discussion on the matter.

Next, VIDA is only telling you the high side pressure. To properly diagnose this problem, you need an ac gauge set, which will tell you both the low AND high side pressures. It's useful to verify the high side pressure from VIDA, but in this case, you're more interested in the low side pressure. Normally, an evaporator temperature of 40 deg F ought to correspond to a low side pressure of about 35 psi, but since you're using an alternative refrigerant, you'll have to look up the pressure-temperature chart for it. Normally, the vents will be a little hotter than the evap temperature due to parasitic heat gain of the air as it travels to the vents.

_IF_ the evap temp sensor matches with the low side pressure, and the vents are still "way above that", then it's possible you're getting re-heated air from a faulty heater control valve not shutting off the flow of hot water to the heater core. I haven't looked for this valve on my V70, but know it to be a common source of re-heating issues in general. Sometimes a cable adjustment on the heater control valve is necessary; sometimes the valve itself is faulty.

A/C diagnostics generally consist of the following;

1) Certainty that system was charged by weight to specified system capacity

2) Ambient temp (measured ~2" in front of condenser)

--measurements taken with a/c on high, doors/windows open, engine at 1500 rpm--

3) Vent temp

4) Low side pressure

5) High side pressure

Item 1 is one of the most important items, and also the most frequently ignored one, which can easily lead to an incorrect diagnosis.

BTW - your listed location is pretty close to Arizona Mobile Air - the sponsor of the online store ackits.com and their associated a/c diagnostics forum. I have no affiliation other than a satisfied customer, but if there was 1 place I'd trust to fix my A/C, it'd be them.

Next, VIDA is only telling you the high side pressure. To properly diagnose this problem, you need an ac gauge set, which will tell you both the low AND high side pressures. It's useful to verify the high side pressure from VIDA, but in this case, you're more interested in the low side pressure. Normally, an evaporator temperature of 40 deg F ought to correspond to a low side pressure of about 35 psi, but since you're using an alternative refrigerant, you'll have to look up the pressure-temperature chart for it. Normally, the vents will be a little hotter than the evap temperature due to parasitic heat gain of the air as it travels to the vents.

_IF_ the evap temp sensor matches with the low side pressure, and the vents are still "way above that", then it's possible you're getting re-heated air from a faulty heater control valve not shutting off the flow of hot water to the heater core. I haven't looked for this valve on my V70, but know it to be a common source of re-heating issues in general. Sometimes a cable adjustment on the heater control valve is necessary; sometimes the valve itself is faulty.

A/C diagnostics generally consist of the following;

1) Certainty that system was charged by weight to specified system capacity

2) Ambient temp (measured ~2" in front of condenser)

--measurements taken with a/c on high, doors/windows open, engine at 1500 rpm--

3) Vent temp

4) Low side pressure

5) High side pressure

Item 1 is one of the most important items, and also the most frequently ignored one, which can easily lead to an incorrect diagnosis.

BTW - your listed location is pretty close to Arizona Mobile Air - the sponsor of the online store ackits.com and their associated a/c diagnostics forum. I have no affiliation other than a satisfied customer, but if there was 1 place I'd trust to fix my A/C, it'd be them.

Last edited by webbch; 05-31-2014 at 12:07 PM.

#4

I was apparently writing my post as you made your follow-up. The test you've done so far does appear to suggest a faulty evap temp sensor with regard to the cycling issue. I wouldn't run the system w/o the temp sensor, as you risk evaporator freeze-up. It might seem to work awesome on a really hot day when your using maximum a/c system capacity, but suspect on a slightly cooler day you'll run into major issues.

#5

Thanks for the input. I did have a low side pressure gauge hooked up, and it was reading pretty much where it should. I couldn't get a good baseline on any of the pressures with the compressor cycling on and off so much. It's clear from my test (pulling the sensor out of the airbox) that it was telling my CCM that the condenser was getting too cold and cycling the compressor. I didn't check my low side pressure after pulling the sensor out of the airbox, but the high side looks OK now - and at 35 degrees at the outlet, I'm plenty happy with the performance of the a/c now. I'll just order a new temperature sensor and not worry much unless something breaks (I could easily pay more for a major a/c system repair than I did for the car).

#6

I was apparently writing my post as you made your follow-up. The test you've done so far does appear to suggest a faulty evap temp sensor with regard to the cycling issue. I wouldn't run the system w/o the temp sensor, as you risk evaporator freeze-up. It might seem to work awesome on a really hot day when your using maximum a/c system capacity, but suspect on a slightly cooler day you'll run into major issues.

It's 95 at 10:30am, for example...

#7

An update - even after the A/C was working so well, it would still stop occasionally - all the symptoms matched the too-big gap in the compressor clutch. I measured it, and it was just under 1.0mm, well above spec. And since we've been experiencing some high-even-for-Arizona-in-June temperatures in the 110 degree range, it only makes sense that the difficulty the clutch has in pulling in would be worse here, now.

Anyway, I read through my options, and decided that I really didn't want to pull the compressor bolts, drop the subframe and all the associated fun that goes along with disassembling the clutch and re-shimming it (or more accurately, de-shimming it). I saw techniques involving bread bag clips and zip-ties, but I didn't like either option. I ended up using thin landscaping (green) wire around each of the three supports in two places each, between the clutch hub and plate, which offsets the clutch plate by the width of the wire (about 0.4-0.5mm). As expected, this reduced the gap in the clutch to somewhere around 0.5mm and I no longer seem to have any problems getting the compressor clutch to engage, hot, cold or in between.

I also replaced the airbox temperature sensor, and while this one is more accurate than the previous one, I was still unhappy with the ultimate temperature of the vents, and the amount of cycling the compressor was doing. So I wrapped a couple layers of masking tape around the sensor (to slow down the response so the on/off cycles will be longer). That helped a lot, but my vents were still going down to only about 48 degrees before the measured airbox temperature hit 5 degrees C and cycled the compressor off. I experimented with moving the airbox temperature sensor out of the airbox slightly (pulling about 2.5" of the 4" length out), and I seemed to get a much better (more realistic) response, with the vent temperature falling to 36 degrees or so (at which point it would cycle the compressor off, which is fine - especially since it happens MUCH less frequently than it did before I started).

I just got back from a test drive where the ambient temperature outside was about 102, and the vents were supplying lots of 36-44 degree air (the range due to the compressor cycling on and off). Can't ask for more than that, though I need all of it here in the summertime! I'll have to keep an eye on things to see if there is any sign that the evaporator is freezing up, but I suspect that won't be an issue any time soon.

Anyway, I read through my options, and decided that I really didn't want to pull the compressor bolts, drop the subframe and all the associated fun that goes along with disassembling the clutch and re-shimming it (or more accurately, de-shimming it). I saw techniques involving bread bag clips and zip-ties, but I didn't like either option. I ended up using thin landscaping (green) wire around each of the three supports in two places each, between the clutch hub and plate, which offsets the clutch plate by the width of the wire (about 0.4-0.5mm). As expected, this reduced the gap in the clutch to somewhere around 0.5mm and I no longer seem to have any problems getting the compressor clutch to engage, hot, cold or in between.

I also replaced the airbox temperature sensor, and while this one is more accurate than the previous one, I was still unhappy with the ultimate temperature of the vents, and the amount of cycling the compressor was doing. So I wrapped a couple layers of masking tape around the sensor (to slow down the response so the on/off cycles will be longer). That helped a lot, but my vents were still going down to only about 48 degrees before the measured airbox temperature hit 5 degrees C and cycled the compressor off. I experimented with moving the airbox temperature sensor out of the airbox slightly (pulling about 2.5" of the 4" length out), and I seemed to get a much better (more realistic) response, with the vent temperature falling to 36 degrees or so (at which point it would cycle the compressor off, which is fine - especially since it happens MUCH less frequently than it did before I started).

I just got back from a test drive where the ambient temperature outside was about 102, and the vents were supplying lots of 36-44 degree air (the range due to the compressor cycling on and off). Can't ask for more than that, though I need all of it here in the summertime! I'll have to keep an eye on things to see if there is any sign that the evaporator is freezing up, but I suspect that won't be an issue any time soon.

#8

Nice work! Sounds like you're "faking out" the evap temp sensor a little bit. You're basically removing any "margin" used to avoid freeze-up, but you've fine-tuned it nicely it sounds like. I'd probably have put a thermocouple on the evap to verify it wasn't going below freezing while the compressor was still running, but you've likely got it dialed in pretty well for AZ.

Good catch on the compressor clutch - yeah that's another common reason for the compressor to drop out. BTW - a good test for the clutch is to lightly rap on it when it's off (and you think it should be running). If that immediately causes it to engage, you've found your problem. It's just a little easier than measuring the gap.

Good catch on the compressor clutch - yeah that's another common reason for the compressor to drop out. BTW - a good test for the clutch is to lightly rap on it when it's off (and you think it should be running). If that immediately causes it to engage, you've found your problem. It's just a little easier than measuring the gap.

Last edited by webbch; 06-06-2014 at 07:02 PM.

#9

webbch, thanks. And I agree with you that doing what I did (faking out the evaporator temperature sensor) shouldn't be done lightly. In my case, I had the Vida/Dice unit running so I could see the correlation between the airbox (evaporator) temperature, and the accurate digital thermometer measuring the output from the vent. I certainly wouldn't recommend doing what I did without being able to check the status of all those things (evap temp, vent temp, a/c pressure, etc.). We do probably take our A/Cs a little more seriously here in AZ than most places... ;-)

#10

#11

Hi, Silver_Volvo. Wear in the A/C compressor clutch causes the gap the electromagnet has to close to be too big. This gets worse in the summertime, when the heat further expands the gap, and (I believe) hurts the efficiency of the electromagnet. The symptom is that the A/C will work fine until the engine revs up, or just some random point, and you no longer have a working A/C. It's not the "computer" that shuts off the A/C compressor, but just that the A/C clutch can't mechanically engage until you shut the car off for 5-10 minutes.

On my car, it only happened once in a great while until the heat got extreme (110 degree days already this June in Arizona), at which time it was failing nearly every time I drove the car.

Now, even on a day that's well over 100 degrees F, I have to turn the fan down after the first few minutes because the air coming out of the vents is so cold. I really don't mind... ;-)

Keep in mind that the A/C compressor WILL cycle on and off normally though - when the pressure on the high side of the system gets too high, or when the condenser temperature gets too low. I took steps to reduce the frequency of this cycling (see the details in my previous posts).

On my car, it only happened once in a great while until the heat got extreme (110 degree days already this June in Arizona), at which time it was failing nearly every time I drove the car.

Now, even on a day that's well over 100 degrees F, I have to turn the fan down after the first few minutes because the air coming out of the vents is so cold. I really don't mind... ;-)

Keep in mind that the A/C compressor WILL cycle on and off normally though - when the pressure on the high side of the system gets too high, or when the condenser temperature gets too low. I took steps to reduce the frequency of this cycling (see the details in my previous posts).

#12

A quick 6,000 mile update on my modifications (can you say "road trip"?).

The A/C worked great 'cross country, up until I was getting near St. Louis. It was humid enough that the vents were blowing "smoke". Eventually, the amount of air coming out of the vents got smaller and smaller until the A/C was essentially not working any longer. Parking the car for a trip up the arch and to take in a Cardinals game had it working at 100% again. I can only assume that the airbox itself actually froze up from all the humidity, and the extra-cold operation.

I don't think this will EVER be an issue in Arizona (or anywhere near here, for that matter), though I did re-insert the airbox temperature sensor to prevent any other problems on my road trip (since I was going to be spending a lot of time in humid areas). I'll be pulling it back out a bit to increase the amount of cold I get out of the system now that I'm back in Arizona.

The A/C worked great 'cross country, up until I was getting near St. Louis. It was humid enough that the vents were blowing "smoke". Eventually, the amount of air coming out of the vents got smaller and smaller until the A/C was essentially not working any longer. Parking the car for a trip up the arch and to take in a Cardinals game had it working at 100% again. I can only assume that the airbox itself actually froze up from all the humidity, and the extra-cold operation.

I don't think this will EVER be an issue in Arizona (or anywhere near here, for that matter), though I did re-insert the airbox temperature sensor to prevent any other problems on my road trip (since I was going to be spending a lot of time in humid areas). I'll be pulling it back out a bit to increase the amount of cold I get out of the system now that I'm back in Arizona.

Thread

Thread Starter

Forum

Replies

Last Post

junkmorning

Volvo 240, 740 & 940

1

03-23-2005 10:51 PM