Risky Business ???

#1

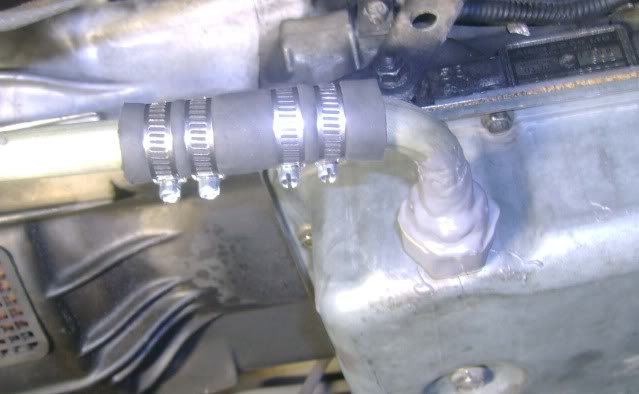

Working on a 1993 240. I forced the issue trying to disconnect the dipstick tube for the transmission. Got it turned just enough to make it start leaking.

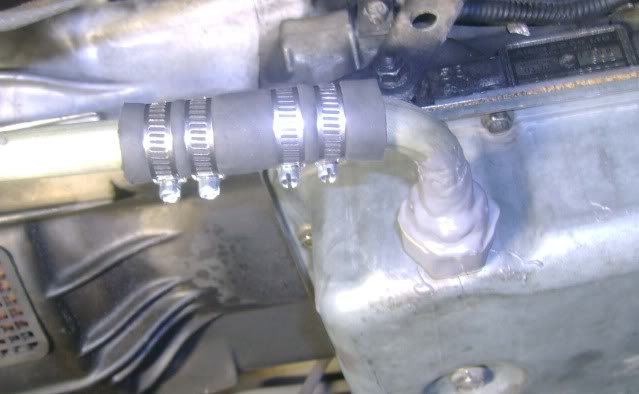

I cut the tube in half. Used 2 applications of JB Weld to seal up the flange nut. this is what I ended up with.

Before I put tranny fluid in it and fire it up I wanted to see if you guys think this will fly until I can get a new pan and dipstick tube.

I cut the tube in half. Used 2 applications of JB Weld to seal up the flange nut. this is what I ended up with.

Before I put tranny fluid in it and fire it up I wanted to see if you guys think this will fly until I can get a new pan and dipstick tube.

#2

I used JB weld as a temp. repair on my 1997 960 fuel rail when the end closest to the front started leaking fuel, and it is still holding. That repair was in Jan, 2009.

I would think the pressure in the fuel rail is greater than the pressure in the filler tube. The only real way to know for certain is to fire it up.

Good Luck

I would think the pressure in the fuel rail is greater than the pressure in the filler tube. The only real way to know for certain is to fire it up.

Good Luck

#3

#4

There should not be any pressure on the dipstick tube...LOL...I tried getting the 2 starter bolts loose and just drop the dipstick tube and tranny pan.

Could not get the top bolt loose and busted out the hack saw. I can get the pan and tube here in Houston for 74.00 dollars but cannot get it till next week.

Thanks for the feedback. This forum has been a wealth of information helping me through the little escapde.

Could not get the top bolt loose and busted out the hack saw. I can get the pan and tube here in Houston for 74.00 dollars but cannot get it till next week.

Thanks for the feedback. This forum has been a wealth of information helping me through the little escapde.

Last edited by Hookem; 10-08-2010 at 07:35 PM. Reason: tyop

#5

I used JB weld as a temp. repair on my 1997 960 fuel rail when the end closest to the front started leaking fuel, and it is still holding. That repair was in Jan, 2009.

I would think the pressure in the fuel rail is greater than the pressure in the filler tube. The only real way to know for certain is to fire it up.

Good Luck

I would think the pressure in the fuel rail is greater than the pressure in the filler tube. The only real way to know for certain is to fire it up.

Good Luck

Thread

Thread Starter

Forum

Replies

Last Post