No Start! Heeeeellllp!

#1

Ok, '94 850 turbo. I changed the head gasket and now no start. The starter cranks over hard, but the engine won't start up

It is getting: spark, fuel, and cylinder compression.

There are no engine codes.

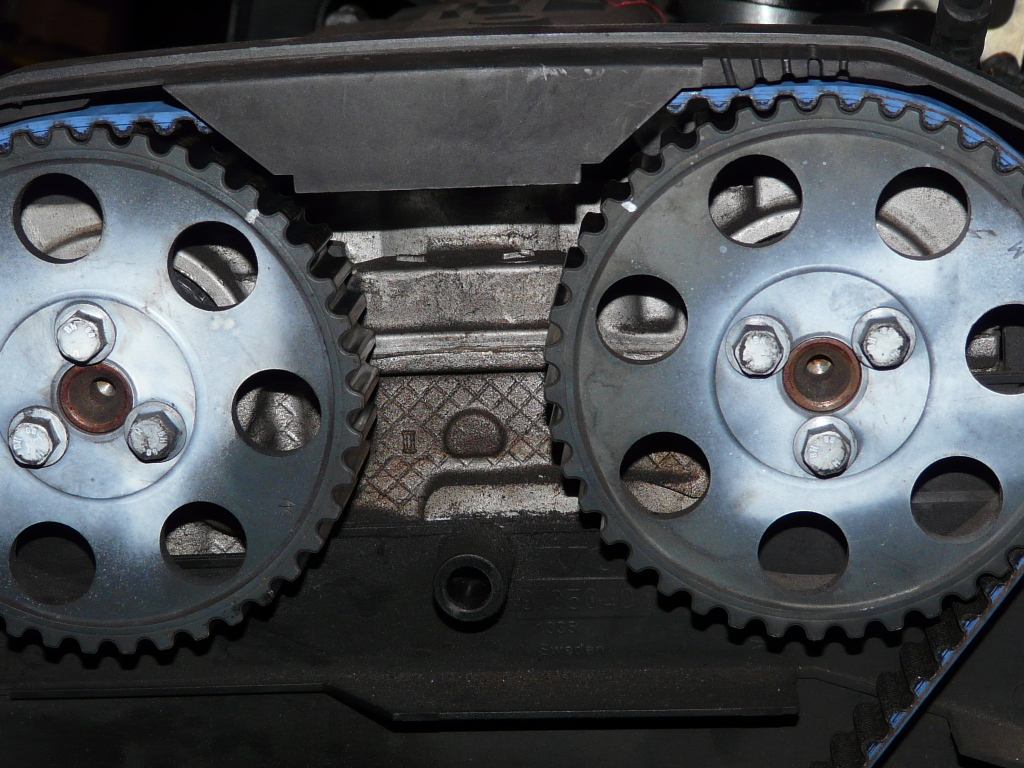

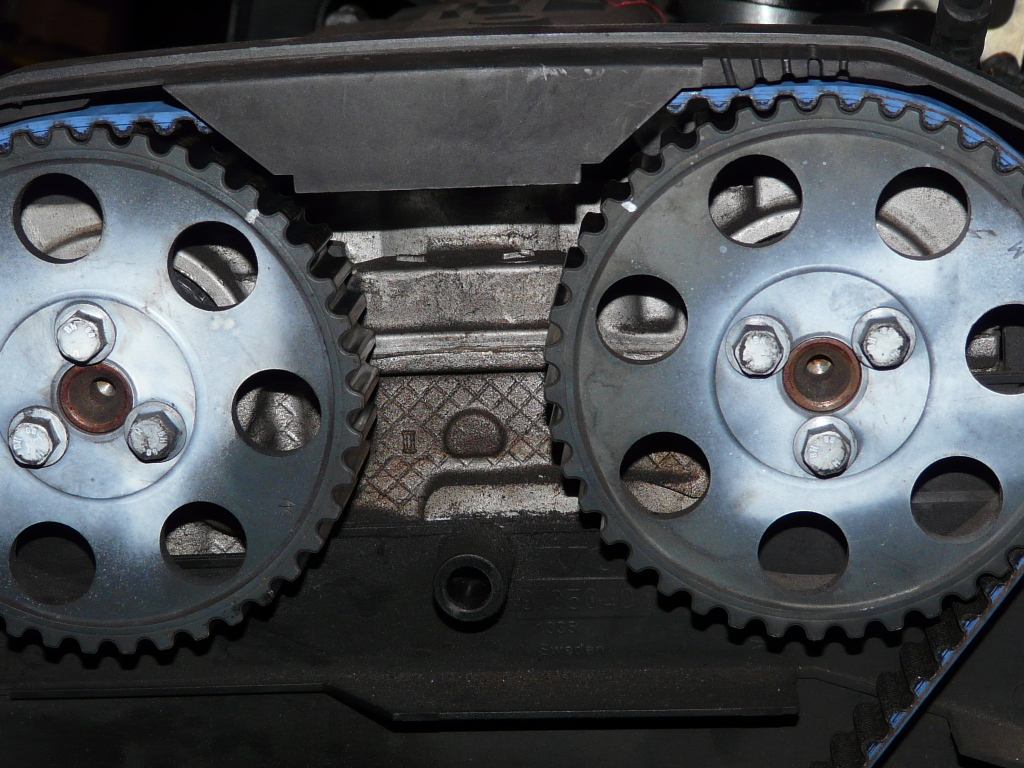

I made sure the timing was correct, and attached some photos showing the positions of the camshafts:

1. The crank pulley is lined up with the notch on the block.

2. The intake cam has 2 bolts on top 1 on bottom; exhaust cam has 1 on top 2 on bottom.

3. The rear of the intake cam has the notch on top and parallel with the top of the head.

4. The rear of the exhaust cam has the notch on bottom and parallel with the top of the head.

5. Another picture of the intake cam gear

Any idea whats going on? Even if the timing is off by a couple gear teeth, the computer should adjust ignition and it should start right?

It is getting: spark, fuel, and cylinder compression.

There are no engine codes.

I made sure the timing was correct, and attached some photos showing the positions of the camshafts:

1. The crank pulley is lined up with the notch on the block.

2. The intake cam has 2 bolts on top 1 on bottom; exhaust cam has 1 on top 2 on bottom.

3. The rear of the intake cam has the notch on top and parallel with the top of the head.

4. The rear of the exhaust cam has the notch on bottom and parallel with the top of the head.

5. Another picture of the intake cam gear

Any idea whats going on? Even if the timing is off by a couple gear teeth, the computer should adjust ignition and it should start right?

Last edited by ahilfman; 05-16-2012 at 07:20 PM.

#2

Looks like you have the exhaust pulley on the intake and the intake pulley on the exhaust. Your cams are not swapped, I can see the 'I' and 'E' in the pictures.

Here is my engine at TDC. Notice the exhaust pulley timing mark is directly in front of a punched hole, the intakes is not. It would be less of a headache if you had them on the right cams.

Here is my engine at TDC. Notice the exhaust pulley timing mark is directly in front of a punched hole, the intakes is not. It would be less of a headache if you had them on the right cams.

Last edited by boxpin; 05-16-2012 at 11:36 PM.

#3

Ok cool, thanks for the pic. I will look at it now. Im just curious though, how close does the timing need to be?? I was under the impression that with a fully computerized ignition system, the computer would adjust spark and fuel to accommodate timing that is a little bit off... maybe a few gear teeth.

Its very frustrating because I don't even know if it is the timing thats off. I am just assuming it is because there is adequate spark and fuel.

Its very frustrating because I don't even know if it is the timing thats off. I am just assuming it is because there is adequate spark and fuel.

#4

#5

Set your cams to be in the center of the pulleys, dont go setting it +/-.

If your concern about TDC, take the #1 spark plug out and set a long screw driver straight down into it till it rests on the piston. Hand move the crank to get it to TDC. (Remember, you have two TDC strokes. You need to get to #1 compression stroke)

Check that your rotor is pointing to your #1 spark plug on the cap.

Yes, the timing is computer controlled but if you put things way out of whack there is simply nothing it can do to compensate. Also, playing with cam timing should come after you have it running, for getting it started put everything back to center.

(tip)My pulleys are painted before I remove the three 10mm so I can put them back in the exact spot when reassembled.

If your concern about TDC, take the #1 spark plug out and set a long screw driver straight down into it till it rests on the piston. Hand move the crank to get it to TDC. (Remember, you have two TDC strokes. You need to get to #1 compression stroke)

Check that your rotor is pointing to your #1 spark plug on the cap.

Yes, the timing is computer controlled but if you put things way out of whack there is simply nothing it can do to compensate. Also, playing with cam timing should come after you have it running, for getting it started put everything back to center.

(tip)My pulleys are painted before I remove the three 10mm so I can put them back in the exact spot when reassembled.

Last edited by boxpin; 05-17-2012 at 02:39 PM.

#6

#7

#8

...sounds like ahilfman also is not running, yet.

we think we have a Bosch P09155738 [motronic 4.3 or 4.4] control ECU. The Chilton manual discusses other systems. There is also an issue that the flywheel [pulse wheel] on the replacement engine has 44 holes, but the markings on our system seem to be 60 [2 of which are blank].

Fortunately, the 'old' mill [with rod extending from case] is still in the 'junkers' yard, so tomorrow we will count the holes on that flywheel. Have you ever heard of such monkey shines? Obviously, if this flywheel [pulse wheel {we have to get used to Volvo jargon, no wonder I can't find stuff in the VADIS search}; then we pull the Pulse Wheel from the old engine and swap to the 'new' engine and may be it will run?

The old mechanical TDL/screwdriver trick doesn't seem right in that the piston doesn't really top out, but I am sure that is not the issue, rather that it just reaches it's "best" highest point.

We trudge onward,and realize that without this Forum, and the guys [n' gals] behind it, we would have already applied a couple of gallons of high test and lit a match!

I love my Volvo's, Rick drives a 'gansta' Buick Park Avenue.

Gentle Ben

we think we have a Bosch P09155738 [motronic 4.3 or 4.4] control ECU. The Chilton manual discusses other systems. There is also an issue that the flywheel [pulse wheel] on the replacement engine has 44 holes, but the markings on our system seem to be 60 [2 of which are blank].

Fortunately, the 'old' mill [with rod extending from case] is still in the 'junkers' yard, so tomorrow we will count the holes on that flywheel. Have you ever heard of such monkey shines? Obviously, if this flywheel [pulse wheel {we have to get used to Volvo jargon, no wonder I can't find stuff in the VADIS search}; then we pull the Pulse Wheel from the old engine and swap to the 'new' engine and may be it will run?

The old mechanical TDL/screwdriver trick doesn't seem right in that the piston doesn't really top out, but I am sure that is not the issue, rather that it just reaches it's "best" highest point.

We trudge onward,and realize that without this Forum, and the guys [n' gals] behind it, we would have already applied a couple of gallons of high test and lit a match!

I love my Volvo's, Rick drives a 'gansta' Buick Park Avenue.

Gentle Ben

#9

...sounds like ahilfman also is not running, yet.

we think we have a Bosch P09155738 [motronic 4.3 or 4.4] control ECU. The Chilton manual discusses other systems. There is also an issue that the flywheel [pulse wheel] on the replacement engine has 44 holes, but the markings on our system seem to be 60 [2 of which are blank].

Fortunately, the 'old' mill [with rod extending from case] is still in the 'junkers' yard, so tomorrow we will count the holes on that flywheel. Have you ever heard of such monkey shines? Obviously, if this flywheel [pulse wheel {we have to get used to Volvo jargon, no wonder I can't find stuff in the VADIS search}; then we pull the Pulse Wheel from the old engine and swap to the 'new' engine and may be it will run?

The old mechanical TDL/screwdriver trick doesn't seem right in that the piston doesn't really top out, but I am sure that is not the issue, rather that it just reaches it's "best" highest point.

We trudge onward,and realize that without this Forum, and the guys [n' gals] behind it, we would have already applied a couple of gallons of high test and lit a match!

I love my Volvo's, Rick drives a 'gansta' Buick Park Avenue.

Gentle Ben

we think we have a Bosch P09155738 [motronic 4.3 or 4.4] control ECU. The Chilton manual discusses other systems. There is also an issue that the flywheel [pulse wheel] on the replacement engine has 44 holes, but the markings on our system seem to be 60 [2 of which are blank].

Fortunately, the 'old' mill [with rod extending from case] is still in the 'junkers' yard, so tomorrow we will count the holes on that flywheel. Have you ever heard of such monkey shines? Obviously, if this flywheel [pulse wheel {we have to get used to Volvo jargon, no wonder I can't find stuff in the VADIS search}; then we pull the Pulse Wheel from the old engine and swap to the 'new' engine and may be it will run?

The old mechanical TDL/screwdriver trick doesn't seem right in that the piston doesn't really top out, but I am sure that is not the issue, rather that it just reaches it's "best" highest point.

We trudge onward,and realize that without this Forum, and the guys [n' gals] behind it, we would have already applied a couple of gallons of high test and lit a match!

I love my Volvo's, Rick drives a 'gansta' Buick Park Avenue.

Gentle Ben

#10

Sorry about that; Boxpin was kinda' answering us both, as my problems seemed to be very similar: anyway, this Volvo is up and purring quietly.

In the end, it was a connector underside, that got oil soaked when the rod came through the block. That alone was keeping us from starting!

Thanks to y'all for your patience and suggestions

Gentle Ben

In the end, it was a connector underside, that got oil soaked when the rod came through the block. That alone was keeping us from starting!

Thanks to y'all for your patience and suggestions

Gentle Ben

#11

I actually have some new info....

The pump works and there is fuel making it to the pressure regulator. However, its not getting through and there is no pressure in the rail!

I replaced the fuel pressure regulator - and the fuel is still not getting past!

The vacuum line is connected without leaks from the FPR to the pvc tree.

There are no codes.

What can be causing this??

The pump works and there is fuel making it to the pressure regulator. However, its not getting through and there is no pressure in the rail!

I replaced the fuel pressure regulator - and the fuel is still not getting past!

The vacuum line is connected without leaks from the FPR to the pvc tree.

There are no codes.

What can be causing this??

Last edited by ahilfman; 05-21-2012 at 07:52 PM.

#12

#13

pump -> fuel supply line -> rail input -> FPR -> fuel return line

On mine the FPR is mounted to the fuel rail; that's the outlet from the rail which goes to the return line.

#16

Ok cool, thanks for the pic. I will look at it now. Im just curious though, how close does the timing need to be?? I was under the impression that with a fully computerized ignition system, the computer would adjust spark and fuel to accommodate timing that is a little bit off... maybe a few gear teeth.

The computer will adjust to a point and the performance will be terrible for each tooth you're off. BUT, the clearance between the valves and the piston doesn't change and each tooth off is closer to a bent valve, cracked head, damaged piston.

#17

So far so good. I made sure the timing was perfect.

There are a few small things... Im getting a 2-3-2 code off the diagnostic box and a P0120 from my scanner. The fuel economy goes down to 15mpg on the streets but goes way up on the highway...and I smell fuel. I replaced every vacuum line but I'll keep checking.

There are a few small things... Im getting a 2-3-2 code off the diagnostic box and a P0120 from my scanner. The fuel economy goes down to 15mpg on the streets but goes way up on the highway...and I smell fuel. I replaced every vacuum line but I'll keep checking.

#18

Thread

Thread Starter

Forum

Replies

Last Post

DecalService

Volvo 240, 740 & 940

10

12-04-2019 10:52 PM

MMAFIGHTER

Volvo S80

16

09-02-2008 08:43 PM

kandio

Volvo S80

3

09-07-2007 05:22 PM